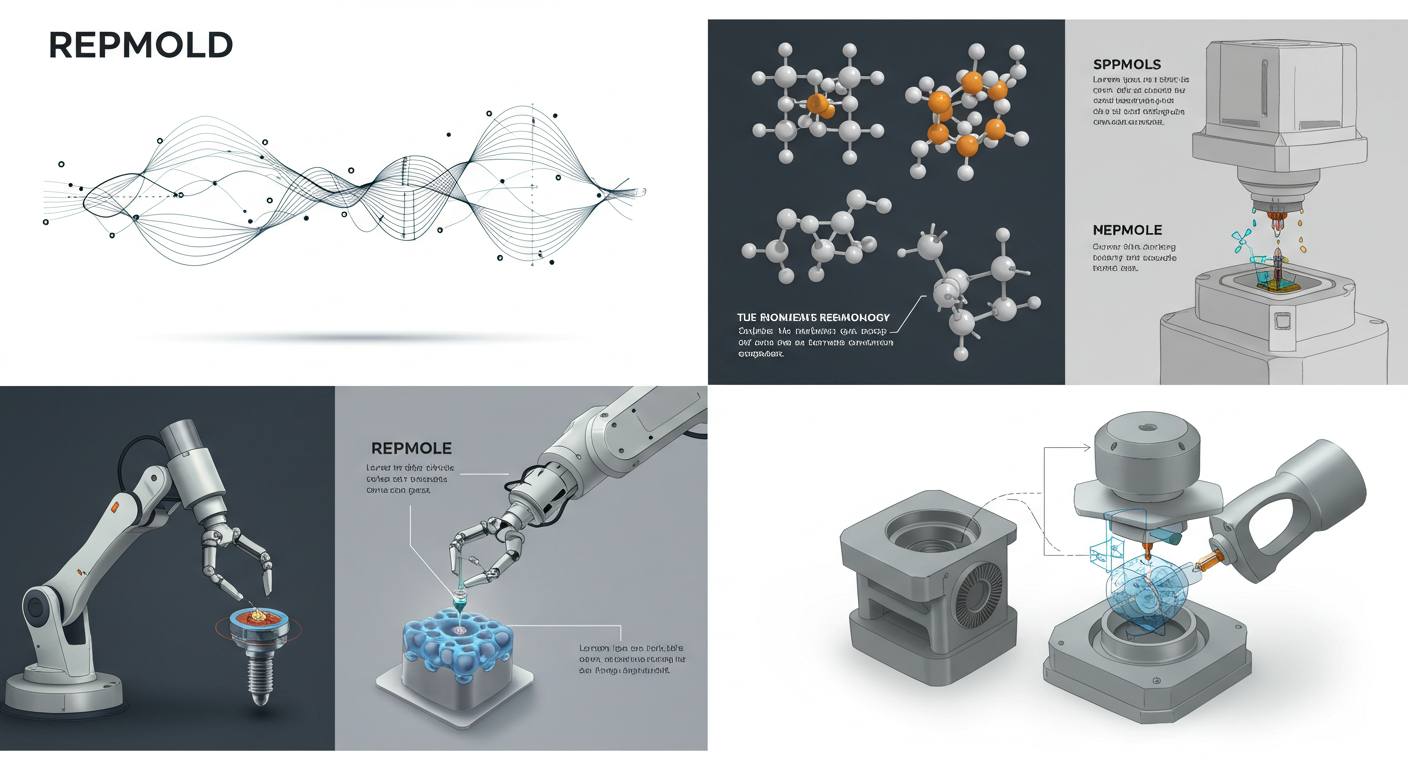

The term Repmold has been gaining attention in various industries, especially in the fields of manufacturing, design, and product development. While the word may sound technical, it actually represents an evolving approach to creating, shaping, and refining products with efficiency. In this article, we will explore what Repmold is, how it works, its applications across different sectors, and why it is becoming such an important concept in today’s industrial and digital landscape.

What is Repmold?

At its core, Repmold can be understood as a process or system that helps in the replication and molding of materials or ideas. It combines the principles of precision manufacturing with innovative technology. The goal of Repmold is to ensure accuracy, reduce waste, and streamline production methods.

Some professionals associate Repmold with physical mold-making in industries like plastics, automotive, or packaging. Others see it as a metaphor for how digital models can be replicated and adapted across multiple projects. In both interpretations, Repmold emphasizes efficiency, consistency, and scalability.

Key Features of Repmold

When looking at why industries are adopting Repmold, several features stand out:

-

Accuracy and Precision – Ensures every product maintains consistent dimensions.

-

Cost Efficiency – Reduces waste and lowers production expenses.

-

Adaptability – Can be applied across different industries and workflows.

-

Sustainability – Supports eco-friendly practices by minimizing unnecessary material use.

-

Innovation Friendly – Integrates well with modern tools like 3D printing and computer-aided design.

Applications of Repmold in Modern Industries

1. Manufacturing

In traditional manufacturing, molds play a central role in shaping products. Repmold technologies enhance this process by making molds faster, more durable, and more precise. Factories benefit from improved speed and reduced error rates.

2. Automotive Industry

From engine parts to interior components, the automotive world relies heavily on molds. Repmold helps ensure that each part meets strict safety and performance standards, while also cutting down on production costs.

3. Packaging

Consumer goods companies increasingly use Repmold-based systems for packaging. These solutions allow for mass production of sustainable packaging materials without compromising quality.

4. Healthcare

Repmold also plays a role in the medical field, especially in producing tools, prosthetics, and equipment that require high precision. The ability to replicate models accurately ensures better patient outcomes.

5. Digital Design and Prototyping

Beyond physical industries, Repmold is used in digital spaces. Designers and engineers replicate models, refine them, and test multiple versions efficiently. This process shortens product development cycles significantly.

Benefits of Using Repmold

Efficiency in Production

The most immediate benefit of Repmold is speed. By reducing manual errors and improving precision, companies can create more products in less time.

Quality Assurance

With Repmold, quality is consistent across batches. Whether a company is producing 100 items or 10,000, each product meets the same high standards.

Reduced Costs

Cutting waste and reducing labor means significant savings. This makes Repmold especially attractive to small and medium-sized enterprises.

Eco-Friendly Innovation

Sustainability is now a global priority. Repmold aligns with eco-friendly manufacturing by minimizing waste materials and supporting recyclable mold processes.

Challenges Associated with Repmold

Like any evolving concept is not without its challenges:

-

High Initial Investment – Implementing advanced molding technologies can be expensive.

-

Technical Expertise Required – Skilled professionals are needed to design and manage molds effectively.

-

Maintenance Issues – Molds require regular care to maintain accuracy and durability.

Despite these challenges, the long-term benefits of Repmold often outweigh the drawbacks, making it a smart investment for forward-looking businesses.

The Future of Repmold

As industries become more digitized is likely to evolve further. Integration with artificial intelligence, automation, and machine learning could make the process even more efficient. Additionally, as sustainability regulations grow stronger, companies may rely on to create greener products at scale.

In the next decade, we can expect to move beyond traditional manufacturing and influence new sectors like aerospace, biotechnology, and even creative industries. Its adaptability ensures that it will remain relevant in a rapidly changing world.

Conclusion

Repmold is more than just a technical concept—it represents a shift toward efficiency, precision, and innovation in multiple industries. From manufacturing to digital prototyping, its applications are vast and growing. Businesses that adopt Repmold today are likely to stay ahead of competitors tomorrow.

By combining sustainability with technological advancement, Repmold is not only solving present-day challenges but also paving the way for a more efficient and eco-conscious future